Specialized tools like metal forming machines, 3D laser scanners, hand tools, and hydro-mechanical lifts are crucial for top-quality frame straightening services. Digital innovations such as laser alignment systems and CAD software, along with robotic welding and 3D scanning, enhance precision and efficiency in collision repair. Safety is paramount, with professional tools featuring advanced safety features meeting ISO/TS 16949 standards, and practices like PPE use and machinery maintenance ensuring reliable frame straightening service.

In the realm of automotive repair, frame straightening service is a critical process ensuring vehicles return to their original structural integrity. This article explores the professional tools and advanced technologies employed in modern frame straightening services. From common hand tools to sophisticated computer-aided adjustments, we delve into the essential safety features and best practices that underpin this vital service. Discover how these methods contribute to the precision and quality of frame straightening, ultimately enhancing vehicle safety and performance.

- Common Tools in Frame Straightening Service

- Advanced Technologies for Precision Adjustments

- Essential Safety Features and Practices

Common Tools in Frame Straightening Service

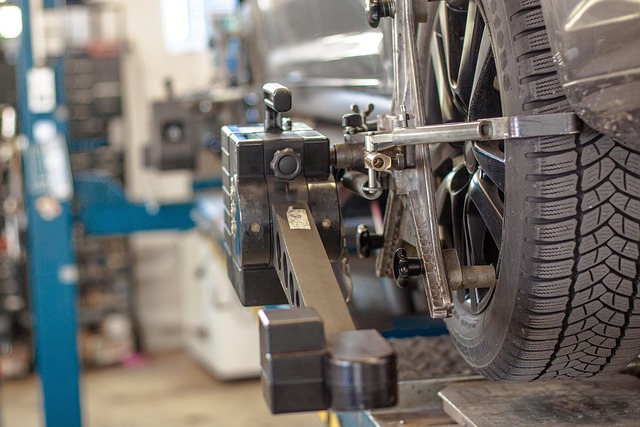

In the realm of frame straightening services, several specialized tools are indispensable for ensuring precision and quality in auto body repair. These include powerful metal forming machines that can accurately adjust and realign car frames, often used in the intricate process of luxury vehicle repair. Advanced measurement systems, such as 3D laser scanners, play a pivotal role in pinpointing exact dimensions, crucial for both precision and aesthetics in automotive restoration.

Hand tools like specialized wrenches, sockets, and clamps also feature prominently. They enable technicians to perform detailed adjustments with manual dexterity. Moreover, the use of hydro-mechanical lifts and advanced jack systems facilitates safe and efficient access to various parts of a vehicle body, facilitating complex car body repair tasks. These common tools collectively contribute to the meticulous art of frame straightening, ensuring each vehicle leaves the workshop in pristine condition, whether it’s a standard sedan or a high-end luxury model.

Advanced Technologies for Precision Adjustments

The evolution of technology has significantly transformed the landscape of frame straightening service work. Advanced technologies like laser alignment systems and computer-aided design (CAD) software enable precise adjustments, ensuring that vehicles return to their original specifications after collision repair or automotive body work. These tools not only enhance accuracy but also speed up the process, allowing collision repair centers to deliver cars back to their owners more efficiently.

In addition to laser alignment and CAD software, modern frame straightening service shops leverage robotic welding systems and 3D scanning technology for even greater precision. Car paint repair processes benefit from these innovations, resulting in seamless finishes that match the vehicle’s original factory standards. This level of craftsmanship not only satisfies customers but also builds trust in the services provided by the collision repair center.

Essential Safety Features and Practices

In any frame straightening service, ensuring safety is paramount. Professional tools designed for this purpose come equipped with advanced safety features tailored to protect both workers and vehicles. These include robust engineering that complies with international standards, such as ISO/TS 16949, guaranteeing structural integrity during intense operations. Auto body shops relying on these tools also prioritize personal protective equipment (PPE) for their staff, reducing risks associated with debris, noise, and vibrations.

Effective safety practices in a vehicle body shop extend beyond the tools themselves. Proper ventilation systems, for instance, are crucial to mitigate hazardous fumes from paint and other chemicals. Additionally, regular maintenance of machinery and adherence to strict quality control measures ensure that every frame straightening service delivered meets high standards, fostering a culture of safety and reliability within automotive body work environments.

In the realm of automotive repair, frame straightening services have evolved significantly, thanks to advanced tools and technologies. From common manual instruments to sophisticated digital systems, these innovations ensure precise adjustments and restore vehicles to their original integrity. By prioritizing safety features and best practices, professionals can deliver high-quality results, enhancing customer satisfaction in the frame straightening service industry.